Product & Service / Product & Environment / Water Level / Pulsar

Water Level – Pulsar

The Pulsar products are always critical to the operation/installation. Our engineers are experienced with the products and someone is always on hand should we ever encounter any issues.

Level measurement is either contacting or non-contacting, measuring continously between the minimum and maximum range or at pre-determined points. Continous measurement usually uses ultrasonic or radar technologies while point measurement is usually contacting, float, paddle or vibrating blade switch.

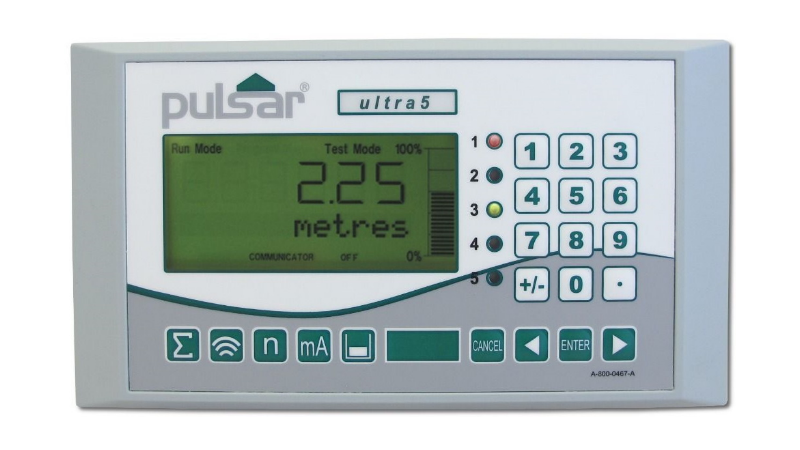

Ultra 5

Ultra 5 provides flexible and reliable non-contacting ultrasonic level and volume measurement, advanced pump control, and measures open channel flow, with different mounting options available to suit the application. The Ultra 5 features the Ultra Wizard, an onboard, menu-driven software tool that allows the user to quickly and simply set up an Ultra 5 unit for a specific application.

Using a ‘Quick Setup’ menu, specific to the application, it allows parameters such as empty and full distances and alarm/control relay settings to be entered. The Ultra Datalogger provides all wall mounted Ultra Controllers with data logging functionality, recording a wealth of information onto the supplied 8 GB Micro SD card, enabling the user to log data for the lifetime of the product.

Blackbox 130

The Blackbox 130 is a compact, low-cost, intelligent controller that offers non-contacting level measurement. Available as a wall mount option with an integral display allowing users to locally program the unit giving an instant indication of level. The Blackbox 130 unit features a 4-20mA output, and two alarm or control relays.

Economical and easy to operate, Blackbox units can be set-up using the integral keypad on the controller and optional interface cable. Benefitting from reliable digital echo processing (DATEM) the unit is able to produce accurate and repeatable level measurement. Compatible with all dB Transducers and mmWAVE Radar sensors, the unit is able to measure from 125 mm (0.41 ft) right through to 40 m (130 ft).

IMP+

The IMP+ non-contacting ultrasonic sensor is designed to be used wherever you need an accurate and reliable level measurement. Its digital echo processing means the IMP+ is perfect for slurries, liquids, or anywhere you need a display telling you the level or analog output to interface with your site control system or drive a display.

There are several measurement ranges available from 0 m to 10 m and each can be wired for 2 or 3-wire operation. All options feature an LCD display and digital temperature measurement and compensation. When combined with Pulsar’s PC Suite, users are able to download, analyze and store echo profiles, set up the IMP’s parameters, install the new firmware to your IMP, and add a flow curve to be able to configure level to flow linearization.

mmWAVE Radar

Our Radar technology is complementary to the ultrasonic range from Pulsar. Giving those ‘difficult’ criteria applications an extra option. Radar is perfect for those kinds of applications where there are changing atmospheric conditions or heavy vapors or fumes. Thanks to Linear Frequency Modulation (LFM) processing, our FMCW Radar technology has a strong signal to noise ratio and excellent resolution, giving it significant advantages over pulsed Radar systems. As with all sensors from Pulsar Measurement, the Radar sensor is retrofittable to all Pulsar Controllers, so whenever your application needs change, your instrumentation can change with you at a minimal cost.

dBi HART

The dBi HART series is a range of self-contained, intelligent, non-contacting, ultrasonic level measurement transducers, which take advantage of HART communication protocols which makes plant integration simple. The transducers can be programmed as stand-alone devices, using HART as the mechanism for data collection, via the dBi HART PC interface.

To add to the dBi’s capabilities, Pulsar Measurement also offers a Device Type Manager (DTM) meaning that users can communicate with the dBi HART Transducers using FDT framework applications such as PACTware. Benefitting from world-leading DATEM technology, the transducer is able to zero in on the echo from the true target, ignoring the stationary echoes from other elements in the measurement path; eliminating the commonly seen loss of echo problem.

dB Transducers

The dB ultrasonic range of transducers range from 3 m measurement range right up to 50 m measurement range and provide a reliable level, volume, open channel flow, pump control, and differential measurement, within both liquid and solids applications. The sensors benefit from highly accurate and repeatable ultrasonic technology and a low power design with standard interconnecting cables – producing extremely high acoustic power to give exceptionally high results in a wide variety of challenging applications.

The non-contacting design of the transducer means they can be fitted with zero interruption to service, and there’s no time consuming maintenance needed. We offer a wide range of options for our transducer range to suit the application. For example, a shield can be fitted during manufacturing to keep the transducer face clean and dry in applications at risk of submergence, PVDF versions of transducers are available for applications where there are chemicals present, and many more.

All dB Ultrasonic Transducers and dBR Radar Transducers are retrofittable with the Pulsar controller range, so if the needs for your measurement change, your measurement system won’t have to.

Pulsarpoint 200 Series

Pulsarpoint 200 Series is a vibrating level switch for bulk solid applications. When solids material comes into contact with the vibrating probe, the frequency of oscillation changes. This is detected and a signal generated to provide a changing relay output. May be used to signify a material level as being high, intermediate or low depending on configuration chosen.

The design of the thin blade profile and the frequency of oscillation ensure that the probe is able to resist material build up, often associated with tuning fork designs. This provides long, trouble free operation.

The Pulsarpoint 200 Series is suitable for most granular products with a bulk density of 20g/litre or more. A relay output is standard. The electronics are mounted in a diecast aluminium housing. The process connection and probe are in stainless steel. An adjustable sensitivity setting allows easy adjustment to suit the material being monitored.

Pulsarpoint 300 Series

The Pulsarpoint 300 series provides effective management of material storage and flow, empty vessels, clogged or blocked chutes or conveyors, and provides prevention of overflows. The ideal applications for this product are usually found in food and beverage, animal feed, pharmaceutical, chemical, plastics, quarrying, power generation, cement, and other industrial-like industries. They are perfect for those applications that require accurate level measurement of solids.

The Pulsarpoint 300 series uses a rotating paddle, the paddle’s rotation is interrupted when the material reaches the paddle, causing a clutch to disengage the motor. This in turn actuates a relay allowing an alarm signal to be switched. The product is fully configurable and can be used to signify high, intermediate, or low-level material.

Pulsarpoint 800 Series

The Pulsarpoint 800 series is designed for very reliable operation when controlling the level of non-potable water and sewage. All units have been designed for maximum durability and dependability, and have a wide-angle operation to enable user-adjustable pumping ranges from one pump switch. The units feature a specially designed seal that bonds the cable into the float, preventing water ingress, while allowing flexibility and ensuring reliable operation. With 3 different options available, all designed with the end-user at the very heart – there is sure to be a pump control float switch that is suitable for your application.

Pulsarbar 700 Series

Pulsarbar is a range of pressure and level transmitters that are perfect for demanding applications throughout industry and the utilities. They are exceptionally stable and combine advanced sensing technology with modern manufacturing methods to provide a superb pressure transducer with very long life. All Pulsarbar pressure transducers are submersible. The robust measurement cell provides good overrange protection and, with accuracy of at least 0.25% fsd, you can specify Pulsarbar with confidence. Typical applications include borehole level measurement, sumps, tanks and basin depth.

Product & Service

Information

Multiproof Company Limited

Head Office : 47/102 Moo.7

(Krisada Nakorn Village 10)

Saotonghin, Bangyai, Nonthaburi 11140

Contact

Tel. (+66)2-1569922

Fax. (+66)2-1569922 Ext 8

Email : product@multiproof.com